Details

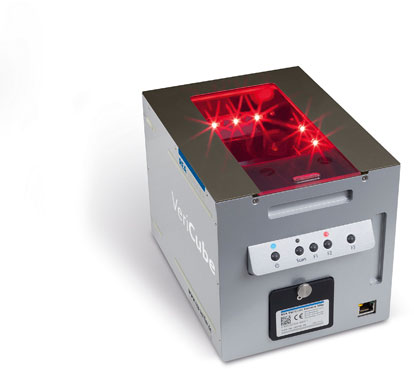

The REA VeriCube is a state-of-the-art matrix and barcode verification device which can be used across all industry sectors. Whether lying, standing or from top to bottom, virtually any test sample can be measured contact-free in the optimum measuring position.

The measurement of optical codes in compliance with defined angles, distances and lighting allows accurate and reproducible measurement results and quality evaluations.The measuring system is based on a high-precision optical module with a CMOS camera chip. The system is designed to avoid ambient light influences during the measurement process. With the REA VeriCube you can quickly find out how to improve the read rate of the tested codes. Optimize the print quality of your codes by utilizing detailed measurement results.

Με τον REA VeriCube μπορείτε γρήγορα να μάθετε πώς μπορείτε να βελτιώσετε την ταχύτητα ανάγνωσης των κωδικών που τεστάρατε και να βελτιστοποιήστε την ποιότητα εκτύπωσής τους, αξιοποιώντας τα λεπτομερέστατα και αξιόπιστα αποτελέσματα κάθε μέτρησης.

Main Features:

- Universal, stationary 2D code verification device

- High-quality aluminum housing, powder-coated, lacquerd with glass cover

- Easy exchangeable and scratch-resistant glass cover

- Different ligthing options (UV, Red, White and IR)

- Compact dimensions (200 x 150 x 150 mm)

- REA VeriCube Standard: Top plates with threaded holes to mount fixtures

- REA VeriCube Pharma: Top plates without threaded holes

- REA VeriCube Inline: PLC variant for integration in machines and plants

- Contact-free measurements by a CMOS camera

- Easy exchangeable camera modules to adapt to different code sizes

- Capable of measuring DPM codes (direct part marking)

- Designed to operate in 3 positions to meet different measuring requirements: sidewise, in upright position and upside down

- Darkened measuring chamber to avoid ambient light influences

- Verification according to ISO/IEC 15415 for printed matrix codes

- Verification according to ISO/IEC TR 29158 (formerly AIM DPM guideline 2006) for direct part marking matrix codes

- Verification according to ISO/IEC 15416 or ANSI X3.182 for barcodes

- Verification in compliance with GS1 specifications

- Verification of GS1-128 data structures

- Verification of optional parameters for optimizing the print process

- Multilingual user interface and reports

- For ease of use, settings can be stored in customized profiles for fast selection

- ISO/IEC 15418 / ANS MH10.8.2 data structure analysis

- Specific code selection to meet the pharmaceutical industry demands

- Power supply via network cable (Power over Ethernet)

- Network-compatible PC evaluation software TransWin 32 for Windows (multi user capable)

- Option Audit Trail for 21 CFR part 11 and CGMP requirements optionally available

Additional Information

| SKU | PN12756 |

|---|