Self Adhesive Labels

Eπίσης, δείτε Συστήματα Barcode & POS.

Types of Adhesives

Classification of Adhesives

• Dispersion Adhesives

- Water

- Acrylic or based on Rubber

• Thermal Melting Adhesives

- solids melting during production

- based mainly on rubber

• Solvent Adhesives

- Acrylic or based on Rubber

- toll coated by a partner

• UV- Acrylics

- thermal fusion with photo reaction

- based mainly on rubber

What affects the ability to attach?

• Properties of the substrate

- How rough or smooth the substrate is

- Humidity

- Substrate stability

- Surface tension

- Shape

• Temperature during labeling

• Conditions after marking

- Resistance to oxidation and UV light

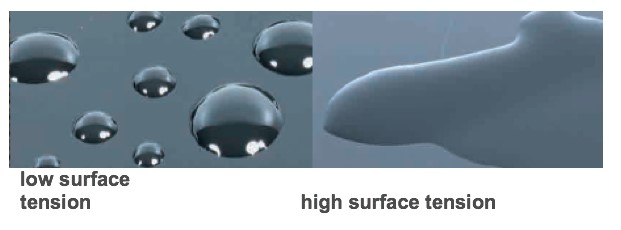

Substrate: surface tension

• Surface tension is the property that makes the surface of a liquid behave as if it were covered with a thin elastic skin

• To liquefy the adhesive on a substrate, there is a basic rule: the surface tension of the adhesive must be • In other words, liquefaction occurs if the adhesive has a stronger adhesion to the substrate than to itself. When this happens, the glue flows to the surface without difficulty and it is easier for the adhesive to stick to the substrate. • Acrylics have a fairly high surface tension and adhere well to substrates with a high surface tension -> high surface tension means easy labeling, and good adhesion eg: glass, steel, polyamide, PET, PS -> low surface tension means greater critical adhesion, but in some modifications it can be reduced eg: PE, PP, Teflon • Note: Long-term removal of high surface tension substrates is demanding. The surface tension of the adhesive is lower than the surface tension of the substrate, which leads to good wetting and increased adhesion after a few weeks of labeling.

Substrate: shape

• Shape

- Curved substrates, such as tubes and small bottles or box corners, are the most common difficult labeling profiles.

- In a convex radius the label material tries to return to its original flat shape and an adhesive with high internal strength (cohesion) is required to keep the label attached, to avoid flagging.

- Label flexibility is an important factor. A very rigid label is not suitable for a very curved substrate

-> Label with: thin face + suitable glue with the appropriate fibers is the solution

Marking temperature

• The properties of adhesives are affected by temperature, but with some adjustments they can be improved.

• Adhesives soften with increasing temperature: this is a result of the reduced internal strength that helps the glue to flow. If the glue becomes too soft it begins to lose its adhesive properties and tends to diffuse.

• Adhesives become harder as the temperature decreases:

- In deep freezer, a normal glue is very fragile and without adhesion (-20 ... 0) -> 149DF, RP48, RH3

- At room temperature, the final adhesion of the adhesive is quite good

- In cooling area (0 ... + 5 degrees C) you must make sure that the choice of glue is correct -> RH1, RP51

• The ideal labeling temperature is room temperature

• It is recommended to use high-strength adhesive for applications with high temperature requirements

Resistance to oxidation and ultraviolet light

• Oxidation means aging

• High temperature increases the oxidation rate

• Acrylics are not as sensitive to oxidation, which gives them a longer life

• Rubber-based adhesives contain components that are more sensitive to oxidation, but with the use of stabilizers the oxidation rate can be reduced, so that their service life is similar to that of acrylics.

• When oxidation occurs, the adhesive begins to turn yellow and loses its adhesion properties. It becomes hard in the long run and is no longer sticky.

• Ultraviolet light (sunlight) is the most critical element when the materials of the label faces are transparent - rubber is not recommended, while UV-acrylics perform better.