Self Adhesive Labels

Eπίσης, δείτε Συστήματα Barcode & POS.

Face Materials

Papers and Films

Papers

Uncoated Papers (Vellum)

Use in e.g. logistics labels

Coated Papers (Raflacoat Plus, Raflagloss, Castgloss)

Use in e.g. food labels

Coloured Papers (Fluor)

Use in e.g. price tags

Metallic Papers (Silver, Goldvac, Foil) (Metal Papers)

Use in e.g. labels that need to be polished to get attention

Functional papers

Thermal Papers (Thermal Top, Thermal Eco) (Thermal Papers)

Use in e.g. product weight / price tags

Thermal Transfer Papers (Transfer Xtra, Transfer Matt) (Thermal Transfer Papers)

Use in e.g. logistics warehouses

Laser printable Papers (Jetlaser, Jetlite, Lasergloss) (Paper for laser printers)

Use in e.g. small offices, craftsmen working from home

Ink Jet printable Papers (Jetlaser, Jetlite, Jetgloss) (Ink Jet Printers)

Use in e.g. small offices, craftsmen working from home

Special Papers (Tamperproof, Boards, Opaque) Special Papers Tamperproof, Boards, Opaque)

Use in e.g. security applications / areas

Filmics (Labels Plastic / White / Transparent)

PE (Polyethylene - Polyethylene) (85, 100 and 150 mm)

Use in e.g. personal hygiene products

PP (Polypropylene - Polypropylene) (30 to 90 mm)

Use in e.g. personal hygiene products and transparent labels

PET (Polyester - Polyester)

Use in e.g. durable nameplates / name / professional title etc.

PP

Advantages

• Ability to produce very thin labels

• Excellent transparency

• Excellent rigidity

Disadvantages

• Topcoat printing only

• Does not maintain a uniform form / shape

PET

Advantages

• Excellent resistance to high temperatures

• It does not tear easily

• Excellent resistance to chemicals

• Excellent transparency

• Excellent rigidity

Disadvantages

• Relatively high price

• Does not maintain a uniform form / shape

Category Summary

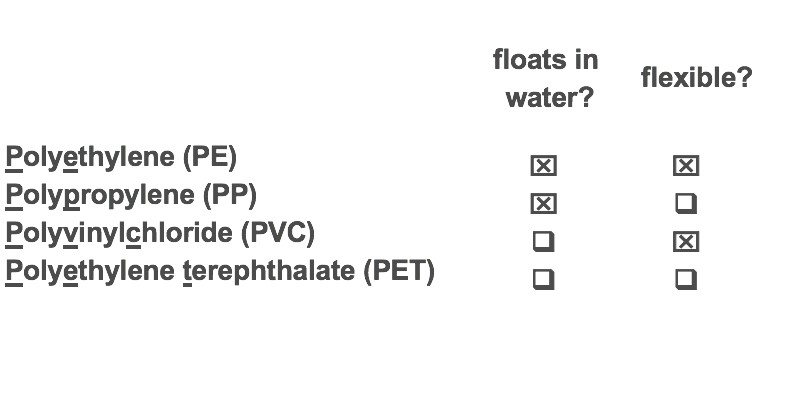

• Polyethylene PE and Polypropylene are the materials most commonly used in this category of labels.

• Colors: White, transparent / colorless and silver.

• Coatings: Matte & Glossy

• Edits: Top coating *

*(These materials are not printable without special processing)

Silicone papers

Glassine

• Highly compressed, special papers

• Translucent for distribution systems with optical sensors (Photocells - Sensors)

• Flexible for excellent operation and distribution

• Sturdy for excellent cutting and conversion properties

• Examples: HG 65 / WG 65 / HD70

Kraft

• Paper with 1 or 2 sides with clay coating

• Excellent dimensional stability

• Excellent moisture stability

• Excellent rigidity for layflat applications

• Applications: sheets, eg, A4 for laser or inkjet printing

• Examples: KS55, KS70, KS75, KS85

Filmics

• ΡΕΤ ή ΡΡ

• Excellent tear resistance

• Excellent moisture stability

• Excellent operating and distribution capacity

• Very uniform surface = no structure in the adhesive layer

• Applications: clear-on-clear, high-speed applications