Self Adhesive Labels

Eπίσης, δείτε Συστήματα Barcode & POS.

Silicone papers

Glassine

• Highly compressed, special papers

• Translucent for distribution systems with optical sensors (Photocells - Sensors)

• Flexible for excellent operation and distribution

• Sturdy for excellent cutting and conversion properties

• Examples: HG 65 / WG 65 / HD70

Kraft

• Paper with 1 or 2 sides with clay coating

• Excellent dimensional stability

• Excellent moisture stability

• Excellent rigidity for layflat applications

• Applications: sheets, eg, A4 for laser or inkjet printing

• Examples: KS55, KS70, KS75, KS85

Filmics

• ΡΕΤ ή ΡΡ

• Excellent tear resistance

• Excellent moisture stability

• Excellent operating and distribution capacity

• Very uniform surface = no structure in the adhesive layer

• Applications: clear-on-clear, high-speed applications

Oil & Industrial Chemical

Note: Novatron does not print labels.

Safety, information, traceability, and the prevention of stock losses – the label transforms industrial chemicals stored in Intermediate Bulk Containers (IBCs), steel and HDPE drums and many other container types into usable goods.

Adhesive selection needs to take into account the surface energy of polar surfaces like metals, paints and lacquers, and more challenging non-polar surfaces such as HDPE plastic. Other parameters include the smoothness or roughness of the labelled surface, the condition of the surface at the time of label application, and possible requirements for momentary repositionability.

After labelling, the adhesive needs to tolerate the conditions in which containers are stored and transported as well as any contact with the container contents. UPM Raflatac draws on decades of technical expertise to formulate adhesives for these highly demanding applications, for the lifetime of the labelled goods.

Wines, Spirits & Craft Beverages

Note: Novatron does not print labels.

In the competitive wine, spirit and craft beverage industries, it’s all about the brand and how it is portrayed on the bottle. Producers from global brands to small independent companies compete for space on crowded retail shelves, so eye-catching wine and spirits labels provide a powerful edge.

No matter how fine the label face, its design and print work, correct adhesive selection provides a vital technical foundation for accomplishing immaculate visual appeal. While glass is a relatively straightforward substrate for achieving good adhesion, factors such as bottle surface treatments create huge variation in surface energy, which must be 38 dynes/cm or above.

Bottle contours and especially the lifecycle conditions of the product also present a challenge. Bottles may be cold and moist during label application. Temperature and humidity will certainly fluctuate during transport and long durations in storage. Extended refrigeration and ice bucket conditions may also be considerations. The various risks include label slide resulting in poor alignment during label application, edge-lift, bubbling and creasing.

Wine, spirit, and craft beverage adhesives from UPM Raflatac perform to the most demanding technical requirements, so that brands perform to the highest expectations.

ADHESIVES

RP30

Compelling presentation for the lifecycle of the label

Maintaining compelling presentation throughout the lifecycle challenges of wines and spirits takes a dedicated adhesive like RP30. This adhesive provides all the required properties for labelling champagnes and sparkling wines, whites, reds, roses and all spirits and liqueurs.

High initial tack provides excellent adhesion on the dispensing line and prevents label slide, even on moist and cold surfaces.

Good accommodation of fluctuations in temperature and humidity keeps labels looking their best without bubbling or creasing, from the bottling line, to transport and storage, to serving. RP30 also retains good hold in ice bucket conditions and provides good resistance to edge-lifting for reliable presentation on bottle necks when combined with recommended face materials.

RP30W

Efficient wash-off for returnable bottles

In the wash-off process for returnable bottles, the RP30W adhesive separates from bottles and stays anchored to the label face. This leaves the wash water uncontaminated and yields residue-free bottles for optimal presentation when recirculated. In particular, RP30W retains good wash-off performance following a variety of storage conditions for used bottles – including storage outdoors. This is where many wash-off adhesives fail, and where RP30W makes the difference. RP30W also performs reliably on label dispensing lines even in cold conditions.

WITH FILMIC FACE STOCKS

RC7W is specially designed for wash-off film labels on PET beverage bottles destined for recycling. During the wash-off process in hot caustic, gravity separates label materials with RC7W from ground-up PET bottles. This separation produces pure, food-grade polyester suitable for re-use as bottles.

RP37

Clear, strong and resilient adhesion

RP37 is a multipurpose adhesive for label films in combination with paper liners, with properties well-suited to wine and spirits labelling. Strong adhesion combines with good resistance to water and UV, for resilience in a variety of conditions.

RP74

High transparency ‘no-label look’

RP74 is designed for a quality no-label look on transparent containers such as PET and glass. It is combined with clear label faces on PET film liners to encourage a smooth and clear adhesive wet-out. Long-lasting clarity is assured by excellent resistance to water-whitening once labelled.

RP76E

Enduring clarity, exuding quality

RP76E is specifically designed for ultra-clear bottle labelling. It is combined with clear film faces and filmic liners to produce a smooth adhesive layer for an optimally clear adhesive wet-out.

With excellent UV-stability and resistance to whitening when exposed to water and ice-bucket conditions, the enduring clarity of RP76E reinforces perceptions of quality.

RC7B

Wet bottle labelling clarity plus pasteurization

This UV-acrylic adhesive for film label faces has excellent resistance to moisture and water. In particular, RC7B provides good adhesion and retains its clarity even when applied to wet bottles.

RC7B’s excellent temperature and water-whitening resistance also make it a good match for applications where bottles are labelled prior to pasteurization.

RC7W

Clean wash-off for recovering food-grade PET

RC7W is specially designed for wash-off film labels on PET beverage bottles destined for recycling. During the wash-off process in hot caustic, gravity separates label materials with RC7W from ground-up PET bottles. This separation produces pure, food-grade polyester suitable for re-use as bottles.

Face Materials

Papers and Films

Papers

Uncoated Papers (Vellum)

Use in e.g. logistics labels

Coated Papers (Raflacoat Plus, Raflagloss, Castgloss)

Use in e.g. food labels

Coloured Papers (Fluor)

Use in e.g. price tags

Metallic Papers (Silver, Goldvac, Foil) (Metal Papers)

Use in e.g. labels that need to be polished to get attention

Functional papers

Thermal Papers (Thermal Top, Thermal Eco) (Thermal Papers)

Use in e.g. product weight / price tags

Thermal Transfer Papers (Transfer Xtra, Transfer Matt) (Thermal Transfer Papers)

Use in e.g. logistics warehouses

Laser printable Papers (Jetlaser, Jetlite, Lasergloss) (Paper for laser printers)

Use in e.g. small offices, craftsmen working from home

Ink Jet printable Papers (Jetlaser, Jetlite, Jetgloss) (Ink Jet Printers)

Use in e.g. small offices, craftsmen working from home

Special Papers (Tamperproof, Boards, Opaque) Special Papers Tamperproof, Boards, Opaque)

Use in e.g. security applications / areas

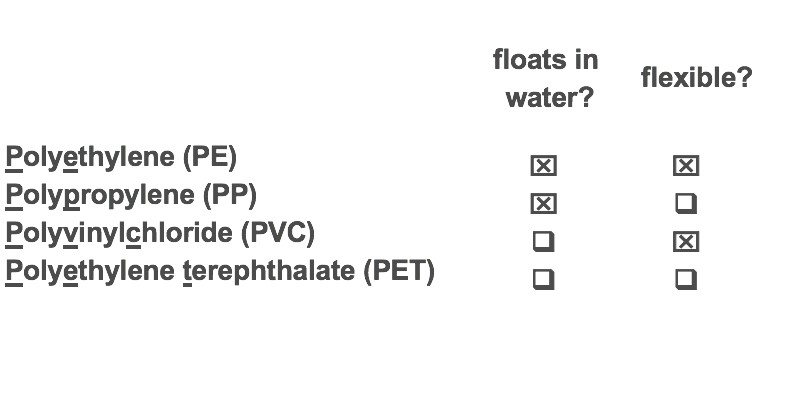

Filmics (Labels Plastic / White / Transparent)

PE (Polyethylene - Polyethylene) (85, 100 and 150 mm)

Use in e.g. personal hygiene products

PP (Polypropylene - Polypropylene) (30 to 90 mm)

Use in e.g. personal hygiene products and transparent labels

PET (Polyester - Polyester)

Use in e.g. durable nameplates / name / professional title etc.

PP

Advantages

• Ability to produce very thin labels

• Excellent transparency

• Excellent rigidity

Disadvantages

• Topcoat printing only

• Does not maintain a uniform form / shape

PET

Advantages

• Excellent resistance to high temperatures

• It does not tear easily

• Excellent resistance to chemicals

• Excellent transparency

• Excellent rigidity

Disadvantages

• Relatively high price

• Does not maintain a uniform form / shape

Category Summary

• Polyethylene PE and Polypropylene are the materials most commonly used in this category of labels.

• Colors: White, transparent / colorless and silver.

• Coatings: Matte & Glossy

• Edits: Top coating *

*(These materials are not printable without special processing)

Food

Note: Novatron does not print labels.

Food safety is a key driver in the food industry. While the label must remain adhered in order to convey the brand, product or price and date information, it must also be a safe solution; there shouldn’t be any risk of the label contaminating the foodstuff. UPM Raflatacoffers solutions that protect the reputations of the label supplier and the brand, by meeting all regulatory requirements for consumer safety.

Food labelling is by far the biggest end-use for self-adhesive labels in terms of volume. It encompasses a wide variety of packaging substrates, from glass to hard and soft plastics, tofibre-based materials like paper and cardboard, as well as metals. Labels are also applied directly onto the surface of the food itself. Label application and service conditions vary widely, from room temperature, to chilled, to deep freeze, and in the dry or when moisture is present.

ΚΟΛΛΕΣ / ADHESIVES

NON-REFRIGERATED TO CHILLED

RP51

This multipurpose, strong permanent adhesive is suited to a wide range of food retail and logistics applications. RP51 adheres well to packaging films, card and corrugated boards, and after labelling retains good adhesion even in chilled temperatures of 0 to 5 C.

RP37

This multipurpose adhesive is for film label faces on paper liners. RP37 provides good adhesion on glass and even plastics, and in food labelling applications where conditions are potentially moist and chilled. RP37 has good resistance to water and UV once labelled. An optimal balance of high adhesion and high cohesion provides clean and stable performance in high-speed conversion and label dispensing.

RF37

This general purpose adhesive for applications in temperatures above chilled conditions is designed for film label faces in combination with filmic liners. RF37 provides good adhesion on smooth plastic surfaces, and has high UV-stability and water resistance once labelled. High cohesion provides good performance in highspeed conversion and dispensing, complementing the productivity of filmic liners.

RH6

ΤRH6 covers a broad range of food labelling applications due to good performance from room temperature down to chilled conditions, on substrates including cardboard and stretch film. These properties make RH6 an especially reliable choice for food logistics labelling.

RH9X

RH9X is specially developed for chilled (0 to 8 C) food labelling on multilayer barrier films typically used for vacuum and modified atmosphere food packaging. It also offers good adhesion to a wide variety of cardboards. For label printers, RH9X provides good matrix-stripping properties due to a smooth release, for fast label conversion and high productivity. For label endusers, RH9X performs reliably with all standard label dispensing methods, with good tack assuring reliable performance in high-speed label application even in demanding chilled temperatures.

RH9X is formulated with an increased proportion of biobased raw material sourced from sustainably managed forests, for improved environmental performance.

RH1

For more demanding conditions requiring aggressive adhesion to cold and moist substrates, RH1 can be combined with both paper and film face materials and is suitable for application to plastic and cardboard packaging in temperatures as low as -5 C.

DEEP FREEZE

RP48

Designed primarily for paper label faces, RP48 provides good adhesion at low temperatures on a wide range of substrates.

RH3

RH3 offers especially good performance in frozen food applications where good adhesion is required on wet and frosty surfaces – as is the case when products are frozen prior to labelling. RH3 is available with paper and film label faces.

149DF

With clear film labels, the water-based acrylic 149DF provides an improved level of transparency compared to hotmelt solutions to enhance shelf-appeal for frozen foods. 149DF also enables fast label conversion with minimal residue-cleaning on die tools for high productivity. Good UV-ageing resistance helps retain adhesive performance and clarity in the long-term. 149DF is supplied with a full range of face materials, both papers and films.

Security & Brand Protection

Note: Novatron does not print labels.

Manufacturers and agencies the world over use security label and packaging solutions to protect items from counterfeiting, tampering and diversion. Self-adhesive labels provide an efficient means of identification, authentication, verification of integrity, and monitoring through the supply chain. They protect consumer safety, brand value, and commercial or governmental revenues.

Anti-counterfeiting labels incorporate specific properties or combinations of features into the face material as a means of authentication. These labels are difficult to reproduce, and depending on the level of security used, their authenticity can be checked by brand owners, government agencies or consumers. UPM Raflatac works with customers to build effective custom solutions and provides a taxi-coating service where customers send security face materials for adhesive-coating and lamination.

Tamper-evident or tamper verification labels are based on destructible papers and films that change appearance or are destroyed when an attempt is made to remove them, break the seals they create, or transfer them onto other products. VOID labels are visibly damaged upon removal and additionally leave a text or pattern adhered to the labelled surface which is extremely difficult to remove undetected.

Very often it is the selection of either a paper-based or filmic label face that is the starting point for adhesive selection in security labelling. This selection is based on cost-efficiency and the requirements of the final application. The choice of adhesive is determined by application-specific criteria such as the smoothness or roughness of the substrate, challenging small diameters, the required strength of final adhesion, and resistance to heat, chemicals, and water from the immediate environment or through attempts to remove the label.

ADHESIVES

FOR PAPERS

RP36 is often combined with thin and flexible paper label faces due to its high cohesion, which supports reliable labelling around package edges or on small diameters.

FOR FILMS

RP37S provides good initial tack and long-term adhesion on polar and non-polar surfaces and performs well in a broad range of security applications such as consumer product labelling and internal logistics. This clear adhesive has good resistance to water, chemicals, oils and UV-light, and excellent UV-stability once labelled.

RP77 is a versatile adhesive for white films and is typically combined with destructible label faces. This high-tack adhesive provides strong final adhesion on rough and textured polar and non-polar surfaces including PE and PP.

FOR HIGH PERFORMANCE

RC18 provides very strong adhesion to polar and non-polar surfaces in long-term applications and demanding conditions. Excellent resistance to water, chemicals and high temperatures also make RC18 very difficult to soak off, chemically remove or lift by applying heat.

RC20 provides very strong, long-lasting adhesion and excellent temperature and chemical resistance like RC18. In particular, RC20 offers high performance on polar and non-polar substrates which are rough, grained or textured.

Self-Adhesive Labels for Beverages

Note: Novatron does not print labels.

The beverage industry is renowned for exceptional branding and marketing to catch the eye of the consumer and stimulate point-of-sale decision-making. Labels need to maintain a high-quality appearance and flawless performance in variable conditions during the lifecycle of the bottle.

During the bottling process, the adhesive must provide good tack in manual and automatic applications, possibly at low temperatures and in humid conditions. Areas where there is inconsistent contact between the label and bottle might not be visible immediately, but can lead to the development of bubbles or creases.

With clear filmic materials supporting a pristine ‘no-label look’ it’s vital that the adhesive remains clear during the life of the bottle. Excellent surface contact is required for good adhesive wet-out to prevent haziness. If exposure to moisture or water will be concerns after labelling, the adhesive needs to be resistant to water-whitening.

ADHESIVES

RP37

Multipurpose and multi-tasking

This multipurpose adhesive is for film label faces on. paper liners, and provides good adhesion on glass and even plastics. RP37 has good resistance to water and UV to retain reliable properties of adhesion for the entire label lifecycle. An optimal balance of high adhesion and high cohesion provides clean and stable performance in high-speed conversion and label dispensing, even in potentially moist and chilled conditions.

RP74

Quality, ultra-clear ‘no-label look’

RP74 is designed for a quality no-label look in combination with clear label faces and PET film liners,which encourage a smooth and clear adhesive wet-out. Long-lasting clarity is assured by excellent resistance to water-whitening once labelled. Good cohesion provides clean and stable performance in high-speed conversion and label dispensing.

RP76E

High-speed, high-productivity labelling

Specially designed for beverage and spirits labelling, RP76E provides good adhesion to smooth polar surfaces like glass bottles and metal and lacquered metal cans. It is supplied with clear film label faces on filmic liners. Excellent UV-stability plus resistance to water-whitening once labelled assures long-lasting clarity.

RP76E’s extra-high cohesion and the strength of a PET liner enable reliable high speeds and high productivity in label conversion and dispensing.

RC7B

Wet labelling clarity plus pasteurization

This UV-acrylic adhesive is designed for bottle labelling applications where excellent water and moisture resistance are required – providing good adhesion and retaining its clarity even on wet bottles. RC7B’s excellent temperature and water-whitening resistance also make ita good match for applications where bottles are labelled prior to pasteurization.

RC7W

Clean wash-off for recovering food-grade PET

RC7W is specially designed for wash-off film labels on PET beverage bottles destined for recycling. During the wash-off process in hot caustic, gravity separates label materials with RC7W from ground-up PET bottles. This produces pure, food-grade polyester suitable for re-use as bottles. RC7W has excellent performance in highspeed dispensing and is resistant to water-whitening once labelled.

Pharmaceutical & Healthcare

Note: Novatron does not print labels.

Our pharmaceutical adhesives are developed, formulated and manufactured to meet industry regulations and safety requirements, including EMA, FDA, and IPAC-RS guidelines. We guarantee long-term stability of supply, with a minimum of 36 months’ rolling availability of unchanged materials and 12 months’ notice in advance of product changes. Full documentary support is provided for validation and approvals.

ADHESIVES

RP80 LT

Low-temperature storage down to -80C with multiple freeze-thaw cycles

RP80 LT is designed to perform in storage conditions down to -80 C. The RP80 LT adhesive also withstands multiple thawing and freezing cycles as samples are thawed at room temperature or in warm or iced water, and later returned to the freezer.

With good mandrel hold, this adhesive is recommended for identification labelling on laboratory vials, ampoulesand test tubes, as well as plates, slides, steel cabinetsand storage boxes. RP80 LT retains its adhesion for extended periods, on surfaces including glass, steel, cardboard and PP.

RP Cryo

Cryopreservation labelling down to -196 C

Cryogenic storage stops time for countless tissues, cell types and subcellular materials. But if these biological samples can’t be identified, they are lost forever.

UPM Raflatac label materials based on the RP Cryo adhesive withstand steam autoclave sterilization and cryopreservation conditions down to -196 C, in both vapour phase and liquid nitrogen. This adhesive is extremely resistant to thermal shock, and provides a strong and enduring bond to polypropylene (PP) cryogenic vials, tubes and storage boxes.

RP Cryo also withstands multiple thawing and freezing cycles, further ensuring that valuable biological samples are identifiable for the duration of their cryogenically extended lifetimes.

RP31 Purus

Migration-safe labelling for liquid drugs in plastic containers

RP31 Purus is a ‘migration safe’ adhesive with low leachable characteristics. Leachables are compounds that leach from packaging because of direct contact with the drug product under normal storage conditions and could potentially be dosed to a patient. Migration is a concern particularly for drugs in liquid or gaseous form, stored in containers made from plastic materials.

RP31 Purus performs well on small diameters and curved surfaces, and on a variety of labelling substrates including PP, PE and low-density polyethylene (LDPE). LDPE is widely used for squeezable nose or eye-drop containers, where migration safety is critical.

The FDA has assigned Drug Master file (DMF) number 25392, type III for RP31 Purus.

RP32 PB

Primary blood bag labelling

Regulatory requirements and the extreme conditions associated with blood storage and processing place stringent demands on labels for blood bags. RP32 PB has been developed and tested according to guidance from the ISO 3826 standard. It withstands temperatures of +121 C during steam sterilization, down to long-term storage conditions of -80 C. It also tolerates freezing in ethanol at -50 C.

RP32 PB has low-leachable characteristics on blood bags and is compatible with various plasticizers used in PVC blood bag manufacturing, including the most common, DEHP.

RP32 PB is supplied with a choice of non-PVC label faces according to market preferences.

RP31, RP31L, RC3P

Labelling small diameters

Small-diameter containers – such as syringes, ampoules, cartridges, pens, vials and test tubes – place special demands on label construction. UPM Raflatac’s research indicates that a diameter of 15 mm is the threshold at which the choice of label material becomes critical. Thin and flexible label faces are supplied with the following adhesives for optimal performance.

RP31 is formulated for labelling curved surfaces and small-diameter packaging. It offers a reliable solution for a wide variety of applications requiring excellent mandrel hold. RP31 bonds strongly to glass, HDPE and PP ubstrates.

RP31L is essential in applications where product identification must be secured by reducing the risk of missing labels to zero. Supplied with clear films, RP31L offers luminescent functionality for missing label detection on label dispensing lines and is a convenient and consistent solution compared to luminescent varnishing on-press.

RC3P is a UV-acrylic adhesive with excellent clarity for labelling on glass and is especially beneficial for visual checks of liquid container contents. Good water, heat and chemical resistance make RC3P suitable for a wide range of applications as well as end-uses requiring resistance to steam autoclave sterilization.

RP3H

Genuinely self-adhesive on surgical sterilization wraps and bags

ΤReusable surgical instruments leaving hospital operating theatres are cleaned, washed, packed on trays and wrapped in non-woven or crepe wrapping material, prior to sterilization by steam autoclave. Allpacks are individually labelled for identification and traceability.

RP3H retains excellent adhesion in the steam, pressure, and heat of the autoclave process, which is typically at 134 C for up to 18 minutes. This adhesive also accommodates swelling and shrinkage of various wrapping materials during and after processing.

Uniquely, RP3H labels are genuinely self-adhesive because no additional sealing tape is required to secure label adhesion. Light application by hand is both convenient and cost- efficient.

Postal

Note: Novatron does not print labels.

While electronic communication has reduced the overall size of the market for postal stamps, demand is growing for special editions for philatelic interests. Requirements are also growing for embedded security features which authenticate high-value stamps.

UPM Raflatac offers considerable resources in materials expertise and product innovation, in addition to security solutions to safeguard postal operators’ revenues. All our label faces, in rolls and sheets, are available both gummed and self-adhesive. We’re also able to develop truly unique products – such as the world’s first flavoured, gummed adhesive postage stamp.

Gummed

This non-self-adhesive, water-activated synthetic gum is designed for moistenable paper coating applications, for example to adhere a postage stamp to letters and other mailed items. This is the traditional ‘lick-and-stick’ stamp adhesive.

Permanent Stamp

More and more countries are moving to permanent stamp adhesives to help prevent stamp re-use. Perm Stamp meets this need when removability by water soaking is not required. Perm Stamp is designed for sheet and booklet conversion, with bleed-resistant properties to avoid sticky edges.

Permanent Stamp Soak-Off

Stamp collectors have traditionally removed gummed stamps from envelopes by soaking, but not all self-adhesive stamps make this easy. If the stamp has to be soaked too long, the paper becomes fragile, and the stamp is easily torn. Permanent Stamp Soak-off is permanent as the name suggests, but removes easily by soaking in water. It leaves stamps intact and free from residue, protecting the value of the stamp for years to come for philatelists, and driving continued enthusiasm for the stamps business. Perm Stamp Soak-Off is designed for sheet and booklet conversion, with bleed-resistant properties to avoid sticky edges.

Types of Adhesives

Classification of Adhesives

• Dispersion Adhesives

- Water

- Acrylic or based on Rubber

• Thermal Melting Adhesives

- solids melting during production

- based mainly on rubber

• Solvent Adhesives

- Acrylic or based on Rubber

- toll coated by a partner

• UV- Acrylics

- thermal fusion with photo reaction

- based mainly on rubber

What affects the ability to attach?

• Properties of the substrate

- How rough or smooth the substrate is

- Humidity

- Substrate stability

- Surface tension

- Shape

• Temperature during labeling

• Conditions after marking

- Resistance to oxidation and UV light

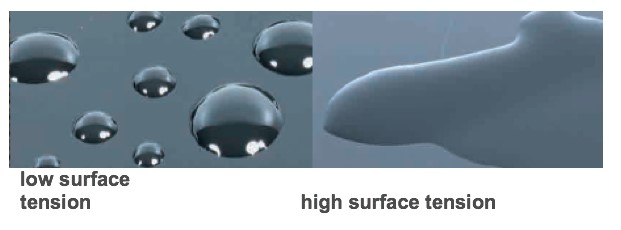

Substrate: surface tension

• Surface tension is the property that makes the surface of a liquid behave as if it were covered with a thin elastic skin

• To liquefy the adhesive on a substrate, there is a basic rule: the surface tension of the adhesive must be • In other words, liquefaction occurs if the adhesive has a stronger adhesion to the substrate than to itself. When this happens, the glue flows to the surface without difficulty and it is easier for the adhesive to stick to the substrate. • Acrylics have a fairly high surface tension and adhere well to substrates with a high surface tension -> high surface tension means easy labeling, and good adhesion eg: glass, steel, polyamide, PET, PS -> low surface tension means greater critical adhesion, but in some modifications it can be reduced eg: PE, PP, Teflon • Note: Long-term removal of high surface tension substrates is demanding. The surface tension of the adhesive is lower than the surface tension of the substrate, which leads to good wetting and increased adhesion after a few weeks of labeling.

Substrate: shape

• Shape

- Curved substrates, such as tubes and small bottles or box corners, are the most common difficult labeling profiles.

- In a convex radius the label material tries to return to its original flat shape and an adhesive with high internal strength (cohesion) is required to keep the label attached, to avoid flagging.

- Label flexibility is an important factor. A very rigid label is not suitable for a very curved substrate

-> Label with: thin face + suitable glue with the appropriate fibers is the solution

Marking temperature

• The properties of adhesives are affected by temperature, but with some adjustments they can be improved.

• Adhesives soften with increasing temperature: this is a result of the reduced internal strength that helps the glue to flow. If the glue becomes too soft it begins to lose its adhesive properties and tends to diffuse.

• Adhesives become harder as the temperature decreases:

- In deep freezer, a normal glue is very fragile and without adhesion (-20 ... 0) -> 149DF, RP48, RH3

- At room temperature, the final adhesion of the adhesive is quite good

- In cooling area (0 ... + 5 degrees C) you must make sure that the choice of glue is correct -> RH1, RP51

• The ideal labeling temperature is room temperature

• It is recommended to use high-strength adhesive for applications with high temperature requirements

Resistance to oxidation and ultraviolet light

• Oxidation means aging

• High temperature increases the oxidation rate

• Acrylics are not as sensitive to oxidation, which gives them a longer life

• Rubber-based adhesives contain components that are more sensitive to oxidation, but with the use of stabilizers the oxidation rate can be reduced, so that their service life is similar to that of acrylics.

• When oxidation occurs, the adhesive begins to turn yellow and loses its adhesion properties. It becomes hard in the long run and is no longer sticky.

• Ultraviolet light (sunlight) is the most critical element when the materials of the label faces are transparent - rubber is not recommended, while UV-acrylics perform better.

Home Care & Personal Care

Note: Novatron does not print labels.

Home and personal care labelling leverages strong brand imagery to attract consumers.

Lasting presentation is a challenge, however, because products are often used in wet and humid conditions over long periods of time. Labels may also encounter a wide range of oils and chemicals from the container contents.

Labels also typically need to flex with squeezable plastic packaging without forming creases. If the label suffers edge-lift or other loss of contact, the adhesive will be at risk of whitening when exposed to water.

WET WIPES APPLICATIONS

Note: Novatron does not print labels.

Wet wipes packs require an adhesive with resistance to oil, chemicals and water to retain good open-closure performance for the duration of the product’s useful life. The adhesive shouldn’t leave any sticky residue, it should help prevent label creases and curls, and it should seal well to prevent content leakage. UPM Raflatac provides two resilient UV-acrylic adhesives which cover the majority of commonly used package types.

RC12 has relatively high tack for applications where a, stronger peel is desired, and provides long-lasting openclosure, functionality.

RC13 suits applications where the preference is for a softer, smoother and quieter peel.

Tyres

Note: Novatron does not print labels.

Tyre labelling presents a real challenge for pressure sensitive adhesives. The roughness of the substrate and the uneven tyre profile severely limit the contact area between the tyre and label. The adhesive must also withstand migration from chemical components of the rubber as well as the wax or silicone-based chemicals often used as mould-release agents during the tyre manufacturing process. Very aggressive immediate adhesion is required.

Tyres are normally labelled in room temperature by hand or increasingly by automatic dispensing. Subsequent storage conditions can vary from room temperature to warmer or colder conditions in warehouses or outdoors. Accordingly, the adhesive must also maintain its properties in low and high temperatures.

ADHESIVES

RHT

The heavy duty RHT adhesive proves its performance every day on the production lines of nearly every tyre manufacturer. This high-tack, high coat-weight adhesive assures excellent performance to minimise re-labelling due to lost labels and assure reliable tracing and identification.

RH40

RH40 is supplied with cost-efficient label stock alternatives for labelling relatively smooth and even surfaces on particular car and motorcycle tyres.

RD50

RD50 is specially developed for tyre manufacturers’ internal logistics. Labels are dispensed onto the side of the rubber tyre before the vulcanisation process which bonds the tyre components and produces the tread.

DESCRIPTION OF SELF-ADHESIVE LABELS

MATRIX – CUTTING / PEELING

RELEASE COATING – PAPER COATING

RELEASE LINER – SILICON PAPER

SELF-ADHESIVE LABEL

FACE MATERIAL – SURFACE MATERIAL

ADHESIVE

There are many different types of self-adhesive labels. Each item has its own type of adhesive that allows the label to adhere to different surfaces depending on the use for which it is intended. Read below for information on the different types of labels and how to use them to choose the right type of labels for your needs. Your label printer should be able to print all the following types of labels.

We offer paper and film labels, specially designed to meet your needs for:

• Product safety - coverage of all relevant industrial and regulatory requirements.

• Durability - ensuring that labels remain intact throughout the life of labeled products.

• Top financial performance - ensuring the ideal balance between cost and performance.

• Sustainability - reducing the environmental footprint of the product and developing sustainable solutions.

Types of Papers

Thermal Economy

A paper with a special thermal coating, which turns black when exposed to a heat source. This type of paper is commonly used to record information on a short-term basis, e.g., listing at point-of-sale stores, scales, logistics, address labels, and terminal box descriptions.

Thermal Top Coated

This type of paper has a protective coating that protects the thermally sensitive area of the label face from damage that may be due to grease, grease, solvents, and plasticizers (usually from packaging film that may come in contact with the labels during storage or transport). This type of label is commonly used in freezer environments for pre-packaged foods (such as meat and cheese) in supermarkets.

Semi-Gloss

Includes a glossy white coating that does not contain wood. This is a paper that is commonly used in colorful prints - in heat transfer, where it is given to the slightest artistic detail.

Vellum (Uncoated)

This is smooth and white paper. It is mechanically processed and does not contain wood. This type is usually used for general purpose applications (such as barcoding and logging general information).

Polypropylene

This paper has a transparent or white glossy film that is used for rigid and durable applications. Includes waterproof materials that allow stickers to be used in cosmetics, personal hygiene items and other advertising applications. A special ink ribbon is required to print on this material, which is compatible with most trusted printers on the market.

Label Adhesives

Permanent

This is the most common adhesive used on self-adhesive labels and, as its name implies, it is permanent (that is, when applied with pressure, it cannot be removed). This type is usually used when the information is important and should not be deleted or changed. The glue has a shelf life of about 12 months (under normal conditions). These conditions will be in a cool or dry environment for most applications.

Temporary / Removable

This is a less common adhesive and, as its name implies, can be easily removed from the surface to which it has been applied. This type is commonly used in promotional marketing (e.g. offer / discount labels), as price tags should be removed without leaving marks, glue residues, etc. on the products, on the shelves. etc. When the glue is left to sit for a long time, however, it becomes more difficult to remove it without leaving marks.

Freezing / Low Temperature (Deep Freeze)

This adhesive is ideal for low temperature environments, although it can be just as effective at room temperature. This type is commonly used for food applications in freezing environments.

In summary, it is very important to keep in mind that the above papers are combined with all types of adhesives, so that you can print the type of label that best suits your needs.

See also Barcode & POS Systems.

Durable Goods

Note: Novatron does not print labels.

Labelling on durable goods emphasizes particular conditions in which the label must perform and the life-expectancy of the label.

Requirements for resistance to exposures including heat, chemicals and solvents, moisture and water, mechanical strain, outdoor weathering and UV light vary widely. But in all cases, information such as model identification, serial numbers and warnings needs to last the lifetime of the labelled product.

Durable labelling is therefore an end-use category where a cross-linked adhesive – for example UV acrylic or catalyst-activated – will likely be required.

This is regardless of how well the labelled surface favours bonding in terms of surface energy, though naturally the adhesive will be adapted to the polarity of that substrate.

ADHESIVES

Electronic and electrical devices and their components and casings are typical examples where select UPM Raflatac adhesives demonstrate excellent durable labelling capabilities – computers, white goods, sports and fitness equipment, power tools, industrial machinery and automotive parts.

Moreover, our advanced non-solvent solutions enable label printers and end-users to move their durables business forward sustainably – and achieve market differentiation through environmental responsibility.

UV-ACRYLICS FOR ENDURING RESISTANCE TO HEAT, CHEMICALS, WATER AND UV LIGHT

Our UV-acrylic adhesives have high internal strength(cohesion) which makes their properties of adhesion resistant to long-term exposure to high temperatures, water, chemicals and UV. This high cohesion is achieved by chemically locking together the molecules in the adhesive with ‘cross-links’, which form during our label stock manufacture when the coated adhesive is exposed to ultraviolet light.

RC15 is specially designed to provide outstanding adhesion on polar surfaces like glass, steel or ABS.

RC18 is designed for films in combination with paper or film liners, in end-uses requiring very good adhesion on polar and non-polar surfaces.

RC20 has a high coat weight for rough and demanding substrates, and has very good adhesion on polar and nonpolar surfaces.

CATALYST ACTIVATED FOR EXTREME RESILIENCE

UPM Raflatac has introduced a new, catalyst activated adhesive (CAA) technology. As with our UV-acrylics, the adhesive undergoes a cross-linking reaction on our coating lines to increase the adhesive’s internal strength. With the ‘RX’ adhesives we have achieved a very high density of cross-links, for extreme cohesion and resilience. The first of this new series is RX15.

RX15 offers label converters and end-users a unique opportunity to combine top-level technical performance with an excellent sustainability profile. RX15 has extremely high adhesion on polar surfaces, good heat resistance and excellent resistance to UV-radiation and chemicals. Applications range from dumper trucks to solar panels and wind turbines.

RP37S

General purpose

For some applications, a film label face such as PET combined with a selected waterborne acrylic adhesive provide sufficient resilience for shorter-term exposure to water, UV and some chemicals. RP37S serves this general purpose need for labelling on both polar and non-polar surfaces.

RP33

Reinforced films and tags

High tack and cohesion make this adhesive particularly suitable for adhesive-on-adhesive applications, where the label or tag material loops back to itself. RP33 is designed for use with tear and cut-resistant reinforced films such as Tyvek and PE White Strong. A typical application is cable-labelling.

RP35, RC35

Film overlamination

UPM Raflatac supplies clear PP and PET overlaminates for lamination over durable labels, for applications where the printed image is at risk.RP35 provides good clarity and UV stability, in applications requiring overlaminated print protection from dirt, water splashes and abrasion.

RC35 is designed for overlaminating film label faces. This adhesive has excellent long-term resistance to heat, chemicals, water and UV.

RC35 also has excellent wet-out behaviour, particularly when supplied on a film liner which produces a smoother surface on the adhesive. This makes it suitable for overlaminating even on dark-coloured label faces where it is difficult to achieve good transparency.

Retail & Logistics

Note: Novatron does not print labels.

Retail labels are applied to goods in stores, from books and home d cor items to shoes and mattresses. They serve a range of purposes: promotional and decorative use, in-store pricing, weigh-scale labelling, size-marking and other informational needs.

Typically, general purpose adhesives are used. In cases, adhesives are dedicated to substrates such as textiles, or they have finely tuned properties for a particular application. Food labelling has a specific range of needs and regulatory requirements and is covered in its own chapter in this book.

For logistics and transport end-uses, self-adhesive labels are typically variable information printing (VIP) products which route, track and trace objects throughout the supply chain, support inventory management, and streamline operations. They often experience significant wear-and tear during their relatively short lifespans, and may require good low-temperature performance on various plastic and cardboard substrates.

ADHESIVES

RP51

Multipurpose performance

This multipurpose, strong permanent adhesive is suited to a wide range of retail and logistics applications. RP51 adheres well to packaging films, card and corrugated boards, and after labelling retains good adhesion even in chilled temperatures of 0 to 5 C.

RHR5

Convenient weigh-pricing on PE bags

The specially adapted RHR5 hot-melt adhesive has balanced performance for convenient tack at room-temperature on PE weigh-price bags, plus good resistance to bleeding for clean, low-maintenance label dispensing. RHR5 is well-matched for weigh-price applications in grocery departments and has the necessary approvals for indirect food contact.

RH6

Shipping and logistics

The RH6 adhesive covers an extremely wide range of shipping and logistics labelling applications. RH6 performs well in chilled and room temperature conditions, on substrates including cardboard and stretch film. Compared to RP51, it also has slightly better cold tack on cardboard.

RR23

Long-lasting removability

RR23 provides exceptional long-term removabilitywith paper labels on a wide variety of substrates in logistics and retail uses. It also performs well on curved surfaces. For food labelling applications, RR23 meets the requirements of EU frame regulation EC 1935/2004, and complies with EU 10/2011 regarding components of food packaging containing plastic in its layers.

RS29

Resealable and repositionable

RS29 is a long-lasting resealable adhesive for filmic open-closure labels on substrates including HDPE, PP and glass. Retail and product labelling with RS29 covers dry goods which are resealed for freshness and convenience. RS29 also provides short-term repositionability with paper labels on a wide range of substrates, making it possible to correct any mislabelling.

RP38 TXL

Residue-free removal from textiles

For textile labelling on retail goods, RP38 TXL balances good tack to keep the label secured with residue-free removal to protect the value of goods.

RP36

Stable performance for luggage tagging

RP36 has increased cohesion to withstand the heat of thermal printing applications while also adhering well to itself when tags are looped back onto themselves. These are ideal properties for luggage-tagging applications.

RP45 & RP45 LW

Wash-off and recirculation for multi-use containers

RP45 and RP45 LW cover numerous rotational applications for plastic and metal crates, boxes, pallets, kegs and other multi-use containers. These adhesives last reliably for the lifecycle of the label and wash off quickly and cleanly for trouble-free container rotation

RP45 is intended for retail as well as standard logistics applications such as plastic transport boxes with smooth surfaces and metal kegs used by breweries. RP45 LW provides greater endurance on challenging rough and patterned surfaces and also in chilled warehouses and deep freeze conditions.

Optimal wash-off is achieved with hot alkaline water, though RP45 is also washable with pure hot water.

ULTRA-REMOVABLE ADHESIVES

RR522U, RR523U & RR524U

UPM Raflatac’s ultra-removable adhesives offer decisive removability where cleanliness really shows and where damage-free surfaces are essential to an item’s value. Clean removal also assists fast and cost-efficient handling.

These adhesives consist of minute adhesive spheres in an adhesive emulsion. This produces uniform, noncontinuous adhesive contact with the labelled surface, resulting in low-tack adhesion and a smooth peel-away.

The RR522U, RR523U and RR524U adhesives offer varying levels of tack for labelling in a wide range of logistics, general branding and retail promotion end uses, on surfaces from glass and white goods to books and newspapers.